Composition

High Pressure Laminate panels are manufactured using cellulose-based materials (approximately 60–70%) combined with thermosetting resins (30–40%). HPL panels can feature decorative finishes on one or both sides. The internal layers consist of kraft paper impregnated with phenolic resin, while the outer decorative layers are impregnated with melamine resin.

The typical structure of an HPL panel includes:

- Overlay: a protective layer for printed decors

- Decorative paper: impregnated with melamine resin

- Core layers: kraft paper layers impregnated with phenolic resin

This composition gives HPL its outstanding mechanical strength, surface hardness and long-term stability.

Performance and Applications

HPL offers exceptional resistance to sunlight, humidity, steam, heat and temperature fluctuations, maintaining both its appearance and functional properties even under heavy-duty conditions. It is available in standard and post-forming grades, with fire-retardant options available on request. Sheet size availability depends on the selected grade and surface finish.

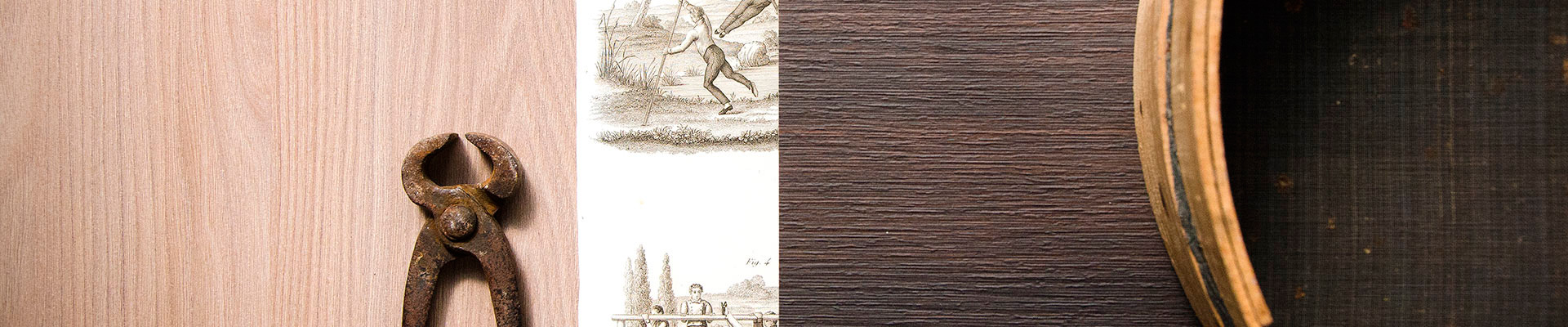

Available Designs

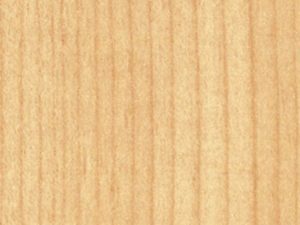

- High Pressure Laminate is an extremely versatile finishing material capable of reproducing a wide range of aesthetic effects. Available designs include:

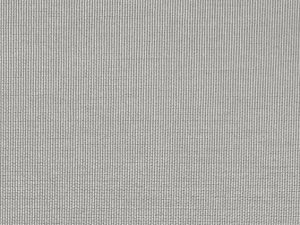

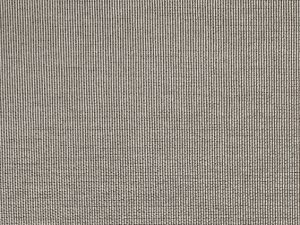

- Unicolor finishes in a broad palette of plain colours

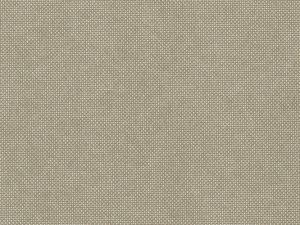

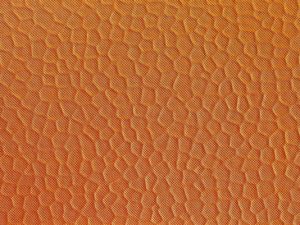

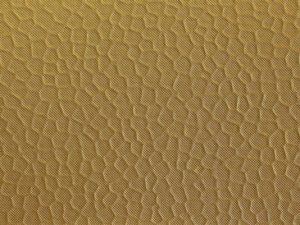

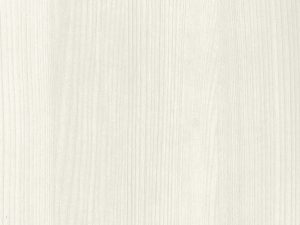

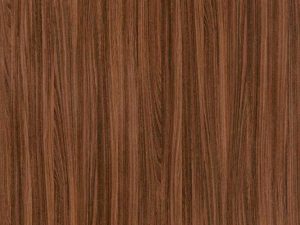

- Woodgrain designs with realistic textures and enhanced surface resistance

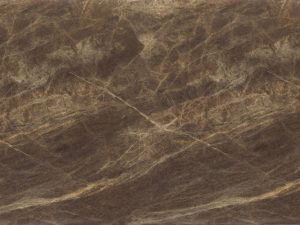

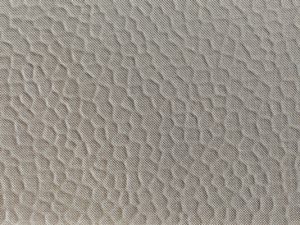

- Stone designs inspired by quartz and marble

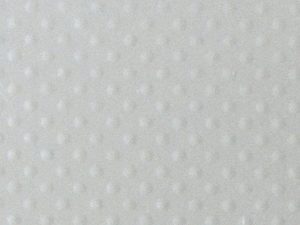

- Fantasy designs with brushed or pearlescent effects

- Magnetic laminates for educational and functional environments

- Wood veneer laminates combining natural veneer with improved durability

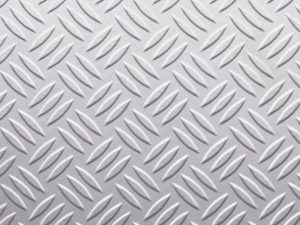

- Metallic finishes with real metal appearance

- Anti-fingerprint surfaces for kitchens, offices and retail spaces

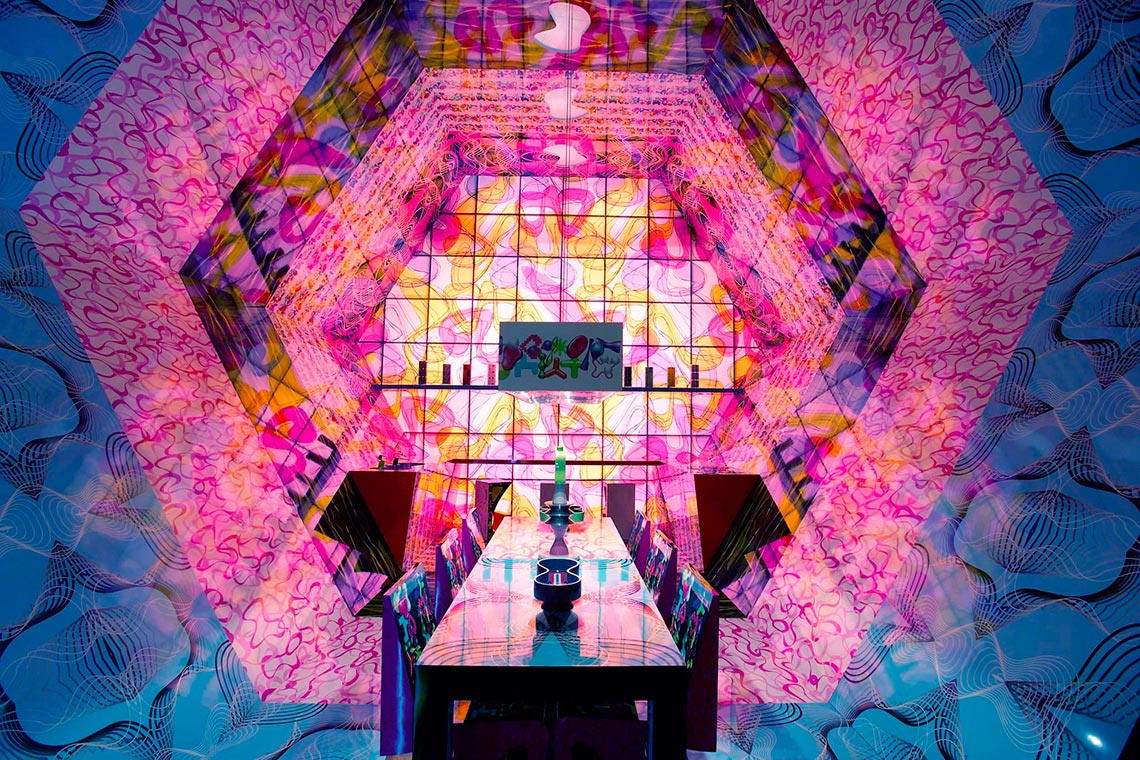

- Digital printing for customised designs